Manufacture of Auger Conveyors

HELI – TRANS

Manufacture of Conveyors

Heli-Trans can make it

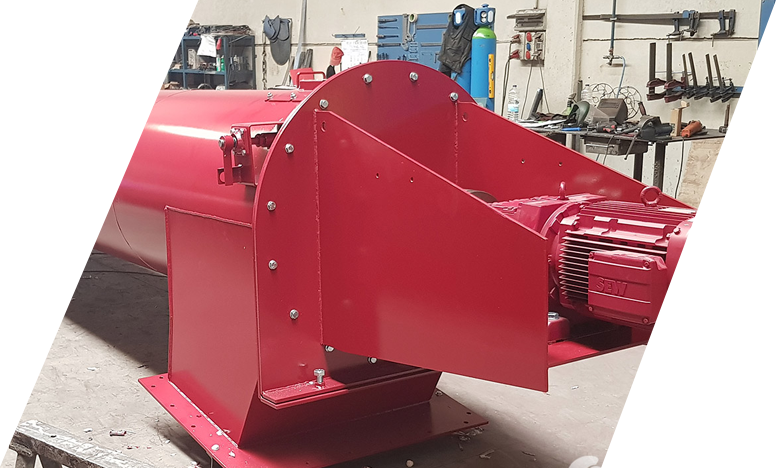

Tube auger conveyors are the solution to a wide variety of transport processes for powdery and granular materials, both in a horizontal and inclined/sloped installation.

Our production means allow us to manufacture equipment with any design and dimensions you need, always under the strict supervision of our technical department.

You can check out our collection of images of finished equipment and see the wide range of machinery we have made in our years of experience. As you will see, if your company has come up with an idea, Heli-Trans can make it.

Heli-Trans can make it

Tube auger conveyors are the solution to a wide variety of transport processes for powdery and granular materials, both in a horizontal and inclined/sloped installation.

Our production means allow us to manufacture equipment with any design and dimensions you need, always under the strict supervision of our technical department.

You can check out our collection of images of finished equipment and see the wide range of machinery we have made in our years of experience. As you will see, if your company has come up with an idea, Heli-Trans can make it.

Among the main types of tube conveyors we make, the following are noteworthy:

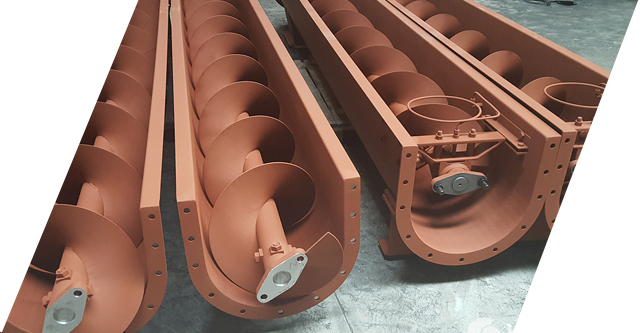

U-Trough Conveyors (TRU)

These systems have a U-shaped trough and screwed-on covers.

They make the maintenance and cleaning of the equipment easier.

They are ideal for abrasive materials.

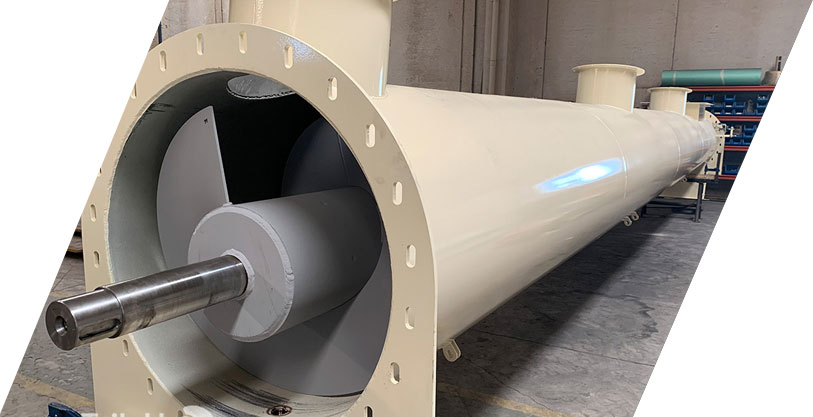

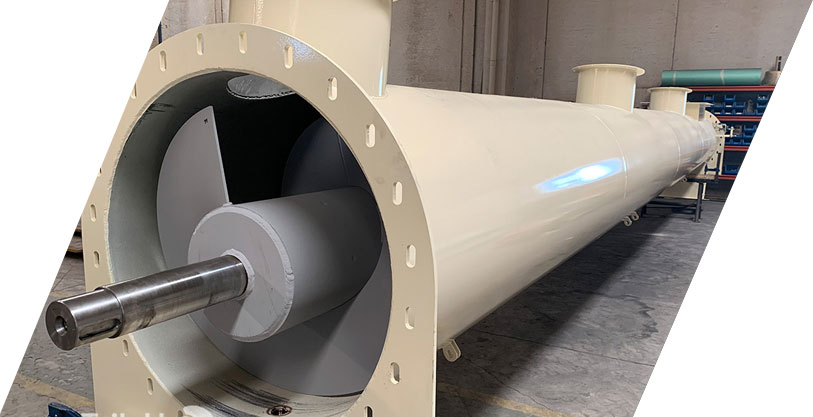

Tubular Conveyors (TRT)

This conveyor type allows for the transport of more material in a smaller diameter.

Not recommended for highly abrasive or sticky materials.

Among the main types of tubeless conveyors we make, the following are noteworthy:

Shaftless Bed Conveyors (TRF)

These systems have a U-shaped trough and screwed-on covers. The auger is shaftless and has an increased thickness. The screw slowly rotates on a high-density, low-friction polyethylene/polythene lining installed at the bottom of the trough, which favors product dragging and silent operation.

Ideal for sticky and fibrous materials.

Sand washers (DES)

These are conveyors with a lining at the bottom of the trough and a small diameter designed for water treatment, separating sand by decantation at wastewater treatment plants, paper mills, etc.

They consist of a hopper for the material to rest as water is decanted at the top and an auger conveyor that extracts the sedimented material, taking it to a container.

our providers

Need help?